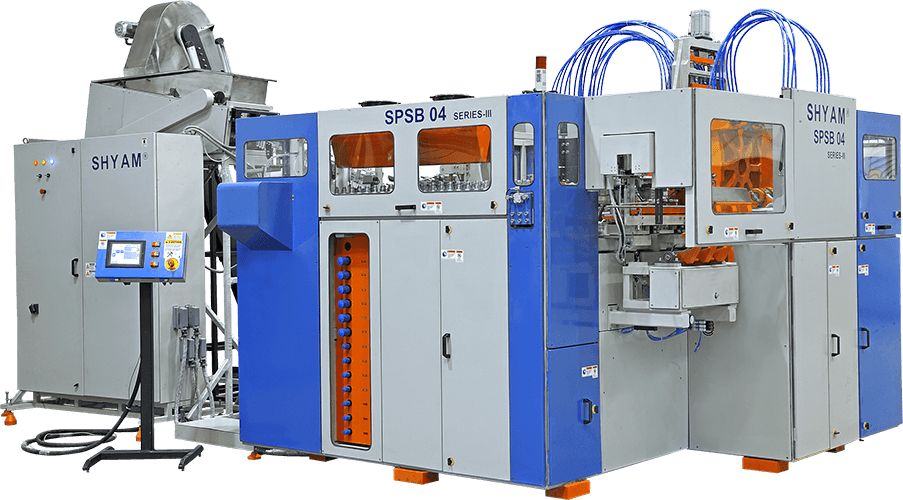

Product Overview

These are two stage pet blow moulding machines that can be used to manufacture round as well as flat style Pet bottles. Being easy and safe to operate, these machines can help you achieve high output, while maintaining the quality consistently. Production rate ranges from 2600 bottles per hour to 5600 bottles per hour. Starting from feeding until the discharging of the bottle, the entire process is completely automatic and is thoroughly controlled by PLC.

Product Specifications

| Description | Unit | SPSB02-2 | SPSB02-1 Series-IV |

SPSB04-0.5 Series-III |

SPSB04-2 Series-2.1 |

SPSB04-2 Series-IV |

SPSB01-5L |

|---|---|---|---|---|---|---|---|

| Machine Specifications | |||||||

| Mould Clamp | Hydraulic | Servo | Hydraulic | Hydraulic | Servo | Hydraulic | |

| Stretching Type | Hydraulic | Servo | Hydraulic | Servo | Servo | Hydraulic | |

| No. of Cavity | No | 2 | 2 | 4 | 4 | 4 | 1 |

| Production Per Hour | BPH* | 2600 | 3600 | 5600 | 5800 | 6300 | 800 |

| Nominal Bottle Volume | ml | 2000 | 1000 | 600 | 2000 | 2000 | 5000 |

| Max Bottle Dia | mm | 105 | 82 | 68 | 105 | 105 | 200 |

| Max Bottle Height | mm | 350 | 300 | 225 | 350 | 350 | 350 |

| Max Neck Dia | mm | 32 | 30 | 30 | 32 | 32 | 45 |

| Air Requirement | |||||||

| H.P. Air @ 32 bar Calculated at |

CFM | 87 (1000ml @ 32 Bar) |

120 (1000ml @ 32 Bar) |

116 (500ml @ 32 Bar) |

183 (1000ml @ 32 Bar) |

207 (1000ml @ 32 Bar) |

103 (5000ml @ 32 Bar) |

| L.P. Air @ 8 bar (without Air Recovery) |

CFM | 36 | 48 | 51 | 65 | 39 | 15 |

| L.P. Air (after Air Recovery) |

CFM | Nil | Nil | Nil | Nil | Nil | Nil |

| Electrical Requirement | |||||||

| Connected Load Without Utility | kW | 35 | 55 | 52 | 66 | 66 | 46 |

| Heating Load | kW | 24 | 48 | 40 | 48 | 48 | 32 |

| Machine Dimensions | |||||||

| Length (mm) | mm | 4750 | 5200 | 5600 | 6200 | 5900 | 5800 |

| Width (mm) | mm | 3800 | 3000 | 2800 | 3600 | 4000 | 3800 |

| Height (mm) | mm | 3300 | 3300 | 3300 | 3300 | 3300 | 3300 |

* Specifications subject to change. *Output varies with bottle design and preform weight & design.

Product Features

Preform Handling

- Robust gripping system in Loader and Ejector, to prevent breakage of grippers.

- Hylam Carriers for longer life and noise reduction.

Heat Conditioning

- Close Loop Heating Control (Auto Temperature Control).

- Positioning of Heaters - Better, Faster and Simpler.

- Individual Heater position adjustable in both axes.

- Dual Neck Protection - Chilled Water and Air Ventilation for Heating Chamber with controllable Vent (for better heat penetration).

Stretching

- Servo Stretching (optional).

- Dual Stretching to reduce cycle time.

- Non Contact Linear potentiometer to achieve Precise Process control.

Mould Clamping Unit

- Mould Clamping using Toggle mechanism for fast cycles.

- Mould Compensation for minimize parting line.

Faster Mould Changeover

- Quick Mould Changeover system.

- No lifting equipment required.

- No need to change cooling lines.

- Less time and efforts required.

Product Application

Production rate ranges from 2600 bottles per hour to 5600 bottles per hour